Don’t miss out!

Get the latest resources sent directly to your inbox.

Your dealership’s fixed operations are essential for sustaining steady revenue and growth, especially during economic downturns. But are you measuring the right service success metrics?

At the April Dealership Insights Forum, dealers gathered to discuss which fixed ops success metrics every dealership should be tracking, how you can incentivize your team, how you can drive more revenue from unclaimed warranties, and more.

The discussion was led by Don Miller, Senior Data Innovation Manager at IDS, Kevin Gribble, former fixed ops manager at Lazydays RV, and Steven Shackleford, Service Director at The Great Outdoors RV.

Here are the highlights from their discussion:

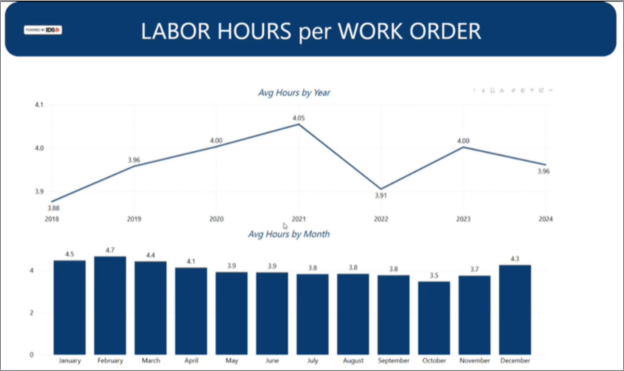

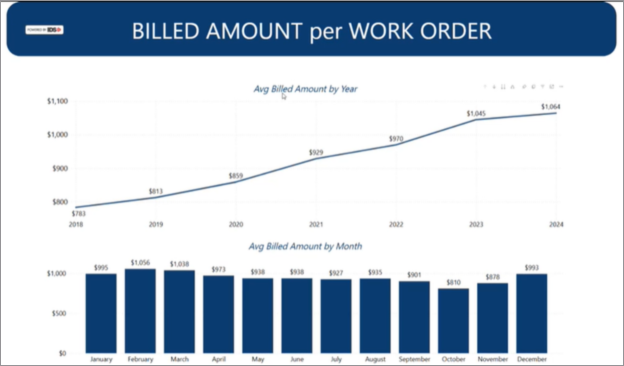

Don Miller kicked off the discussion with a look at national averages for service volume, labor hours per work order, and revenue trends, using IDS’ industry reports.

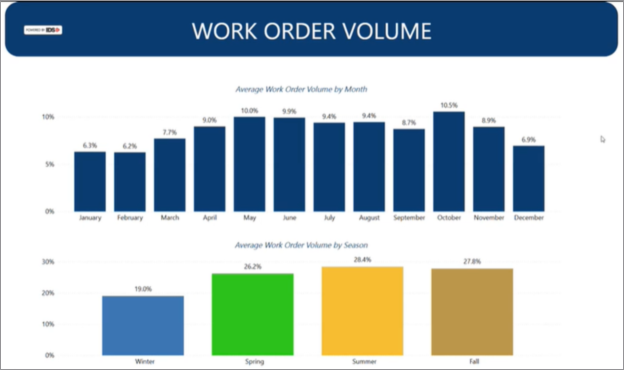

Don Miller: “Looking back over the last 6–7 years, historically, shows that service can be very seasonal.”

One area that has changed considerably over the last several years is dollars per work order.

Don encouraged dealers to track these trends over time, as these insights can be crucial for planning.

Then, the discussion turned to important service efficiency metrics. Some key metrics identified were:

Don Miller: “Those are very important numbers when it comes to the efficiency or productivity of the department. By tracking that over time, you can spot trends and see whether you’re improving or declining.”

Once your track service efficiency, how do you reinforce positive performance within your team?

Steven Shackleford: “I think the most important thing is to keep those numbers at the forefront of your staff’s mind. I track technician efficiency, for example. It’s posted on a board where everyone can see it. I’m tracking the technician efficiencies weekly, and each of those guys knows where they stand in terms of efficiency.”

He also shared how he leverages the Technician Review dashboard in IDS Leadership Insights to manage employee performance: “I keep the historical data for each technician and for the shop as a whole, which allows us to look back and say, ‘You were at 85% efficiency six months ago, and now you’re consistently hitting 110%, 115%. How much of that do you attribute to training you had? What are you doing differently?’ Or, if you see those numbers starting to go down, maybe there’s something going on and you need to have a conversation.”

Pay plans can be tailored:

Kevin Gribble: “There are ways to have either a flat-rate tech or a non–flat-rate tech and still offer incentivized pay plans. We would start with a base rate, and then, if they went over 50 charge hours for the week, their pay rate would increase.

This way, they were incentivized to earn that extra dollar—do a bit more work and push a little harder—because they knew that reaching or exceeding that threshold would result in a significant pay boost.”

Finally, the discussion turned to a topic that has been increasingly on the minds of dealers as the industry navigates slowing sales: fixed absorption.

What is fixed absorption? It’s the concept that a dealership’s fixed ops departments will generate enough revenue to cover the dealership’s expenses minus the cost of sales.

Kevin Gribble: “Our goal was to achieve fixed absorption through warranty work alone. That was always the goal, because if you could figure out how to do it with just that one piece, then everything else was gravy on top.”

One forum attendee shared that they measure fixed absorption using Leadership Insights: “We take the majority of the information from Leadership Insights and incorporate that into the actual payroll times.”

Steven Shacklefold: “The other thing we look at is how much revenue we need to generate per bay—that’s another key piece we consider. It’s not directly related to absorption, but indirectly, it’s kind of aiming for the same number.”

Get the latest resources sent directly to your inbox.