Don’t miss out!

Get the latest resources sent directly to your inbox.

Your dealership’s inventory has a domino effect on all your other departments. Imagine a customer walking into your dealership for a part they requested. However, the part isn’t there when they arrive because the inventory wasn’t updated. You may have inadvertently given the customer the wrong information and hurt your dealership’s credibility in the process. That’s why it’s essential to have good dealership inventory management.

That scenario shows just how foundational your inventory is to your dealership. But many dealerships continue to use inadequate tools and systems for managing their inventory and even guesswork. This prevents them from always knowing what’s in stock. Not to worry – with a little bit of elbow grease, you can fine-tune the process using the dealership inventory management best practices in this guide. We’ll show you step-by-step how you can streamline your dealership’s inventory management.

Step 1: Effective Inventory Counting

Step 2: Get Rid of Dead Inventory

Step 3: Organize Inventory for Profitability

Step 4: Let Your Parts Manager Take Charge

Step 5: Set an Inventory Turn Goal

Step 7: Organize, Plan, Review, Rinse, and Repeat

Are you confident in the accuracy of your inventory numbers?

There’s no getting around an actual physical count of your inventory. But a DMS can easily manage and track inventory, making the overall inventory counting process less labor-intensive. For example, a DMS will allow you to view inventory levels at all locations and view parts sales for each department in one place.

It’s also a good idea to start planning the inventory process at least 12 weeks before the actual count date, and especially to avoid doing it during holidays.

As part of the process, you should prepare the stocking area by cleaning it up and ensuring that everything is where it should be. You’ll also want to get any supplies ready that will help document your procedures, such as cards, clipboards, pencils, etc. Some other helpful tips include:

Monthly Checklist for Dealership Parts Managers

Finally, you’ll also want to designate someone to count the inventory, which will depend on the counting method. There are three ways you can conduct an inventory count:

Count cards and sheets are outdated and less efficient methods than bar code readers. We recommend digitizing your inventory counting process using a DMS that has built-in features for your parts department, so you can manage your inventory levels in one place.

Read Next: 8 Things You Should Be Looking Out for When Shopping for a Dealership Management System

First, break up the counting into small groups. The counting is divided among small groups of one or two people per group, depending on the counting method you’re using. Dividing the counting will alleviate your employees’ stress and prevent them from being overwhelmed at the thought of counting thousands of parts.

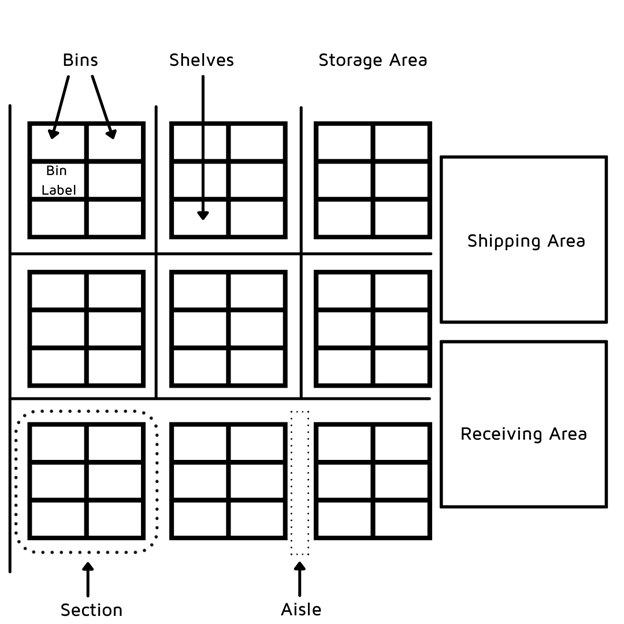

Then, create a map of your stocking area. The map will include details on every shelf, bin, receiving dock, and return area. The map will help you stay organized and keep better track of the count. Divide your stocking area into counting areas and assign your teams to geographic areas rather than product lines. This is because some parts could be located between major product lines and might be missed.

Below is a very basic example of what the map of your stocking area may look like.

Surplus and slow-moving products can also be pre-counted. Then, when it comes time for the inventory count, the bins and shelves will already be marked. This will put less stress on your employees later during the final count. You can then count the items that are the most profitable and are also your fastest movers because these items tend to contain more counting errors.

As teams finish counting their sections, the designated manager should come to verify their counts. Once verified, the counts can be entered into your dealership management system or spreadsheet. If your DMS allows, print and review discrepancy reports. Finally, review and document the counting procedures and processes and meet with your employees to find out what worked, what didn’t, and what can be changed in the future to make the next count smoother.

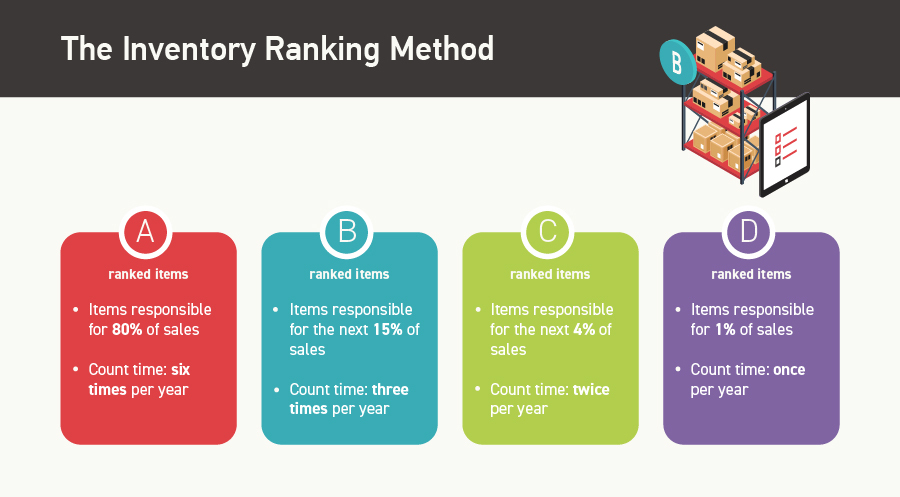

Cycle-counting takes account of different areas of the inventory but over the year instead of an annual inventory count of everything. The benefit is that it makes your inventory and records more precise because you pay more attention to specific areas throughout the year. Although cycle-counting may be difficult during your busiest times of the year, the best way to conduct it is using the Ranking Method.

The Ranking Method works by counting items that bring in the most money more often than your slower-moving products. The ranking method works according to Pareto’s law or the 80/20 rule. Typically, this rule implies that most of your sales will come from a few of your items, i.e., 80% of your sales come from 20% of your items. The number of times a year you count inventory will depend on how you divide and rank them according to the 80/20 rule. See the example below:

Keep in mind that 80/20 is a general guideline. The numbers do not have to be exactly 80% or 20% since it will vary based on your dealership. The rule of thumb is to count the items that are your biggest sellers more often than the least selling items.

Read Next: How This Top 50 RV Dealer Keeps Track of Its Vast Inventory Online and In-Store

If you’re going to get serious about one aspect of your inventory, getting rid of dead and slow-moving items must be a top priority.

If you paid for every item that is stocked on your shelves, the only way you’re going to get any of it back is to sell it. Otherwise, you’ve just thrown hundreds, maybe even thousands of dollars away. Dollars that could be put toward other areas of your business! The bad news is that you’re not always going to be able to get your money back. The good news is that there are many ways you can get these items out of your business, and at least gain back some of what you paid.

It’s not uncommon to have items in your dealership’s inventory that are slow to sell or aren’t selling at all. As you perform inventory counts over time, you will start to notice which parts are typically slow-moving. Take note of those items and keep track of them.

An industry-specific dealership management system will be able to run reports for you that will quickly identify which items are performing worse than others so you can make the necessary adjustments and changes to your stock. Once you’ve identified your slow movers, you can decide what to do with your dead inventory.

Read next: How to Build a Complete Digital Storefront for Your Dealership

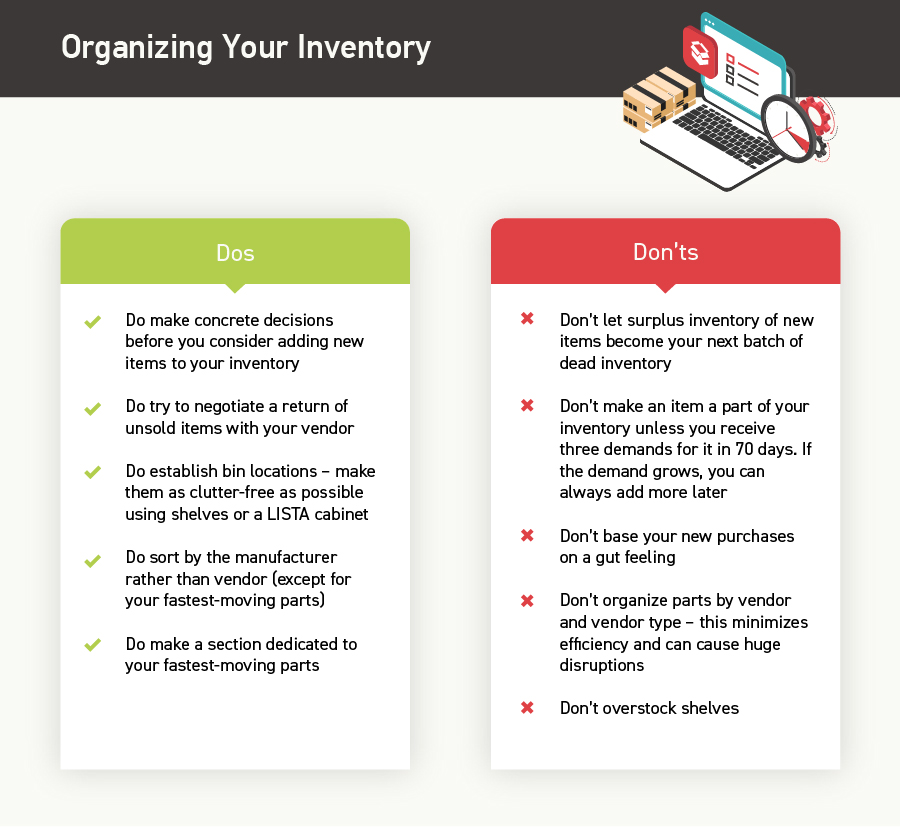

Now that you’ve removed your dead inventory, you will want to organize your remaining inventory in a way that maximizes your dealership’s profitability. Similarly, you will have to decide how you want to organize new items going forward. Here are some guidelines to keep in mind as you organize your inventory:

The fewer people that touch the inventory, the better. Owners are salespeople. They don’t want to do the administrative aspect of the business. That’s why you’ve got to put your trust into someone with more expertise, and that’s your Parts Manager.

Let your Parts Manager be in full control of dealership inventory management. Importantly, this means the Parts Manager should also handle the parts for service writer and technicians. This keeps track of when units are pulled off the shelf and prevents parts from getting lost. It also helps inventory levels and allows your technicians to put in more billable hours because they won’t have to waste time looking for parts.

You can also incentivize your parts manager by setting percentage goals for maintaining a high level of inventory accuracy. For example, if they keep their inventory accurate 95% of the time over a period, offer them a bonus. Ultimately, you want to keep your parts manager more accountable to the inventory.

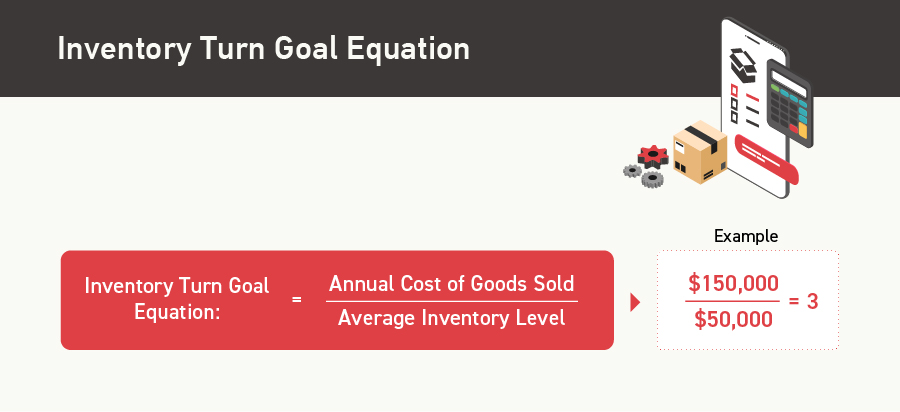

Inventory turn is the number of times inventory is refilled in a year. It’s calculated by dividing the annual cost of goods sold by the average inventory level. For example, if the total cost of goods sold is $150,000 and the average inventory is $50,000, then the inventory turnover ratio is 3. This means you sold and replaced your inventory three times in the past year.

You should set expectations for how much of your inventory you want to sell in a year. It also helps to set goals for how to keep your items moving so money is not tied up and sitting in your inventory. Dealers should have an inventory turn goal of 4 so that only 25% of inventory is on the shelf at any given time.

Have a goal that makes sense for your dealership. For some dealerships, 4 may be too much and you could face the risk of running into issues, such as having items that are out of stock. Again, take into consideration the 80/20 rule and determine which of your parts are fast-moving and which are not so you can plan accordingly.

There will be times in the year when you’ll only want to have a minimal quantity of certain items on hand, such as the slow season. Other times, like the busy season, will require you to have many parts on hand. By the end of the busy season though, you should start to work certain item quantities down.

Setting up minimum and maximum ordering levels for your parts is going to provide you with the most headway in maintaining inventory control. By setting these levels, you’re putting parameters on your parts so that you don’t go too far over or under in ordering a certain item.

Of course, there will be certain times of the year where you’ll want minimal quantities of certain items because you know they won’t sell. That’s why you should have no more than 30% of your peak inventory stocked during the slow season. Once August hits, you should start working those stocking quantities down. This way you’ll have the ability to buy the right parts at the right time and take advantage of manufacturer discounts.

Your minimum and maximum ordering levels should be analyzed on a consistent basis. Review your sales history over the last year and set seasonal levels to prevent overstocking or understocking. An industry-specific dealership management software can help track your minimum and maximum levels so that when levels are low, you can set up an automatic order request.

We get it, inventory management may not be the most exciting part of your dealership. But, it’s still important to be able to plan your inventory by analyzing your sales history and seasonal trends. Your customers’ purchasing behavior will also indicate which merchandise is most popular. This also means taking note of lost sales so that you can plan, and purchase items based on what your customers demand.

The most important thing in planning for the future is to constantly check the past. An effective dealership management system will provide the necessary reports to help you with every aspect of your inventory control. By properly organizing, planning, and reviewing your inventory management system, you can find a system that works for you and make it more efficient over time. Even if you’re a 20-year business veteran and think you know the trends like the back of your hand, you’ll never be in full control without sales history reports.

You can also look to your customers to help you plan ahead. Each time they purchase something from you, they are casting a vote for the merchandise you carry. Make sure you take these votes seriously. Plan ahead to stock the merchandise that’s most popular, not just based on what you like.

Read Next: Key Dealership Metrics to Measure Performance and Plan for Success

Finally, don’t overlook the importance of your Parts Manager in this process. Encourage your parts manager as much as possible since they’ll be the ones in charge of dealership inventory management.

In the long run, having an effective inventory management system will allow you to deliver an exceptional customer experience at your dealership.

To help you stay on top of your daily and monthly parts and inventory management responsibilities, we’ve put together a checklist based on our experience working with hundreds of dealership Parts Managers.

Get the latest resources sent directly to your inbox.